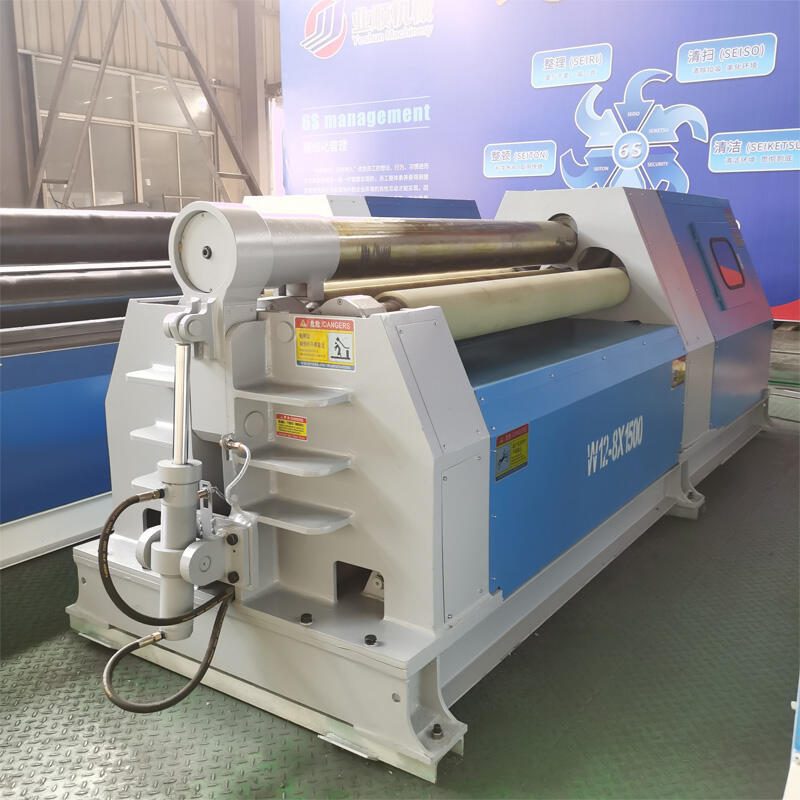

W12 hydraulics plate rolling machine with 4 rolls W12-8x1500

Useful length from 1000mm to 6000mm.

Thickness from 2 up to 100mm.

With our four rolls plate bending machine,plate can be bent on both side without return.Full automatic controlled by PLC,there’s no need for additional processing steps for bending the ends.The flat edge is 1.5-2 times of the thickness.

Quality certificate such as CE and ISO9001.

Description

4 rolls Hydraulic plate bending machine with double pre-bending.

Useful length from 1000mm to 6000mm.

Thickness from 2 up to 100mm.

With our four rolls plate bending machine,plate can be bent on both side without return.Full automatic controlled by PLC,there’s no need for additional processing steps for bending the ends.The flat edge is 1.5-2 times of the thickness.

Quality certificate such as CE and ISO9001.

Specification:

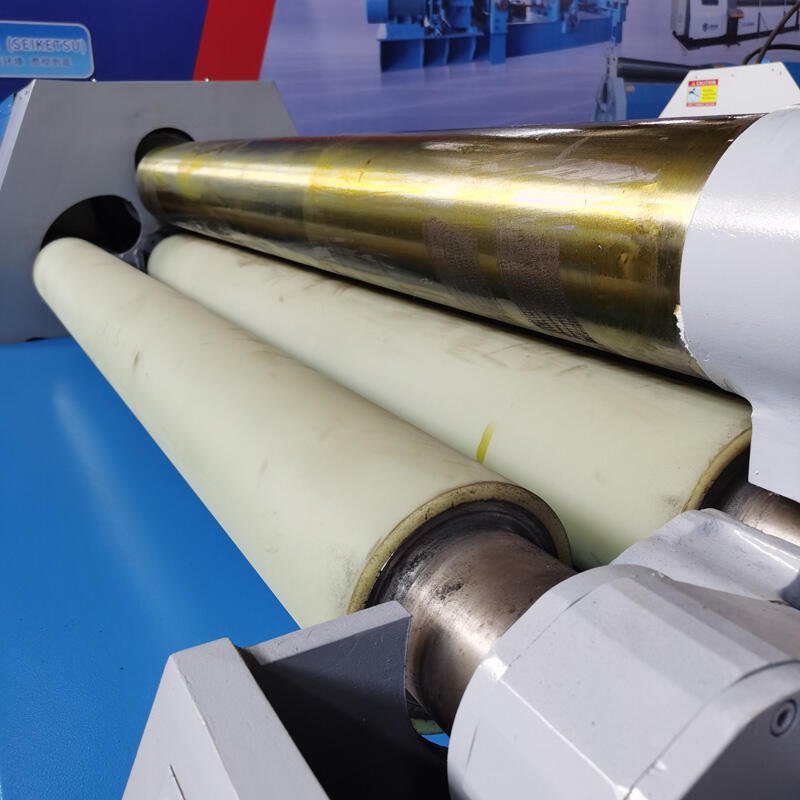

• Pinch roll and lateral rolls move with hydraulic pistons in orbital way;

• Top roll powered by hydro-motor

• Hydraulic drop end for easy removal of finished ferrule

• Easy operation with mobile control panel

• Welded steel frame

• Induction hardened rolls(42CrMo)

• Hydraulic balance system

• Overload protection

Standard component:

• Movable control panel

• Hardened rolls

• Digital read out for both rolls

• Hydraulic station

• Hydraulic motor

• Hydraulic drop end

• Cone bending device

Optional equipment

• Top and lateral support rack for big diameter

• Ground and polished rolls for special job

• Safety cable

• Fan cooled or water cooled

Spare parts brand

|

NO. |

Main Machine part |

Technical Requirement |

|

|

1 |

Working roller |

Material |

42 CrMo |

|

Techniques |

Forging piece go through rough machining then quenching and tempering treatment at HB241~280 |

||

|

Finish turning then medium frequency quenching of surface at HRC40-45 |

|||

|

2 |

Side Frame and Chassis |

Material |

42 CrMo |

|

Techniques |

Side Roller Lift Cylinder Material for 45# forgings, quenching and tempering heat treatment HB217-255. |

||

|

Fixed and tipping side frame and chassis are welding pieces of steel plate |

|||

|

3 |

Drive Device |

Motor |

Hanzhu,Ningbo |

|

4 |

Control Device |

Low Voltage Apparatus |

Siemens,Germany |

|

5 |

Hydraulic System |

Pump Station |

ChangYuan,China Options: Sunny,USA |

|

Valve |

Yuken,Japan |

||

|

6 |

Electrial Control System |

Touchwin from China |

|

|

7. |

Sealings |

Nok from Japan |

|

|

8. |

Bearing |

WFD |

|

|

9. |

PLC Encoder |

Omron from Japan |

|

|

10. |

Other Electrical Parts |

Siemens from Germany |

|

Parameter sheet

|

Model |

Max. Bending thickness(mm) |

Pre-bending thickness(mm) |

Max. Working length of rolls(mm) |

Yield limit (Mpa) |

Top roller diameter(mm) |

Lower roller diameter(mm) |

Side roller diameter(mm) |

Main power (KW) |

|

W12-4x2000 |

4 |

3.5 |

2050 |

245 |

160 |

140 |

120 |

3 |

|

W12-6x2000 |

6 |

5 |

2050 |

245 |

190 |

170 |

150 |

4 |

|

W12-8x2000 |

8 |

6.5 |

2050 |

245 |

210 |

190 |

170 |

5.5 |

|

W12-10x2000 |

10 |

8 |

2050 |

245 |

230 |

210 |

190 |

7.5 |

|

W12-12x2000 |

12 |

10 |

2050 |

245 |

270 |

250 |

210 |

11 |

|

W12-16x2000 |

16 |

13 |

2050 |

245 |

300 |

270 |

220 |

11 |

|

W12-20x2000 |

20 |

16 |

2050 |

245 |

330 |

300 |

240 |

11 |

|

W12-25x2000 |

25 |

20 |

2050 |

245 |

360 |

330 |

250 |

15 |

|

W12-30x2000 |

30 |

25 |

2050 |

245 |

390 |

360 |

300 |

18.5 |

|

W12-35x2000 |

35 |

28 |

2050 |

245 |

430 |

390 |

330 |

22 |

|

W12-40x2000 |

40 |

32 |

2050 |

245 |

460 |

420 |

360 |

30 |

|

W12-45x2000 |

45 |

36 |

2050 |

245 |

510 |

460 |

390 |

37 |

|

W12-50x2000 |

50 |

40 |

2050 |

245 |

550 |

510 |

420 |

45 |

|

|

|

|

|

|

|

|

|

|

|

W12-4x2500 |

4 |

3.5 |

2550 |

245 |

190 |

170 |

150 |

4 |

|

W12-6x2500 |

6 |

5 |

2550 |

245 |

210 |

190 |

170 |

5.5 |

|

W12-8x2500 |

8 |

6.5 |

2550 |

245 |

230 |

210 |

190 |

7.5 |

|

W12-10x2500 |

10 |

8 |

2550 |

245 |

270 |

250 |

210 |

11 |

|

W12-12x2500 |

12 |

10 |

2550 |

245 |

300 |

270 |

220 |

11 |

|

W12-16x2500 |

16 |

13 |

2550 |

245 |

330 |

300 |

240 |

11 |

|

W12-20x2500 |

20 |

16 |

2550 |

245 |

360 |

330 |

250 |

15 |

|

W12-25x2500 |

25 |

20 |

2550 |

245 |

390 |

360 |

300 |

18.5 |

|

W12-30x2500 |

30 |

25 |

2550 |

245 |

430 |

390 |

330 |

22 |

|

W12-35x2500 |

35 |

28 |

2550 |

245 |

460 |

420 |

360 |

30 |

|

W12-40x2500 |

40 |

32 |

2550 |

245 |

510 |

460 |

390 |

37 |

|

W12-45x2500 |

45 |

36 |

2550 |

245 |

550 |

510 |

420 |

45 |

|

|

|

|

|

|

|

|

|

|

|

W12-4x3000 |

4 |

3.5 |

3100 |

245 |

210 |

190 |

170 |

5.5 |

|

W12-6x3000 |

6 |

5 |

3100 |

245 |

230 |

210 |

190 |

7.5 |

|

W12-8x3000 |

8 |

6.5 |

3100 |

245 |

270 |

250 |

210 |

11 |

|

W12-10x3000 |

10 |

8 |

3100 |

245 |

300 |

270 |

220 |

11 |

|

W12-12x3000 |

12 |

10 |

3100 |

245 |

330 |

300 |

240 |

11 |

|

W12-16x3000 |

16 |

13 |

3100 |

245 |

360 |

330 |

250 |

15 |

|

W12-20x3000 |

20 |

16 |

3100 |

245 |

390 |

360 |

300 |

18.5 |

|

W12-25x3000 |

25 |

20 |

3100 |

245 |

430 |

390 |

330 |

22 |

|

W12-30x3000 |

30 |

25 |

3100 |

245 |

460 |

420 |

360 |

30 |

|

W12-35x3000 |

35 |

28 |

3100 |

245 |

510 |

460 |

390 |

37 |

|

W12-40x3000 |

40 |

32 |

3100 |

245 |

550 |

510 |

420 |

45 |

|

W12-50x3000 |

50 |

40 |

3100 |

245 |

610 |

560 |

480 |

55 |

|

W12-60x3000 |

60 |

48 |

3100 |

245 |

670 |

620 |

520 |

75 |